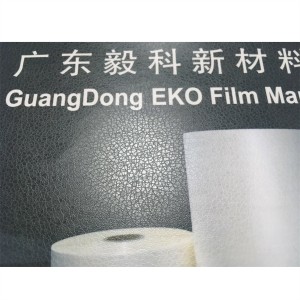

PVC / BOPP Embossing Pattern Thermal Lamination Zaj duab xis

Product Description

Embossing thermal lamination zaj duab xis yog riam phom zais cia uas ntxiv qhov kov ntawm kev ntxhib los mos thiab style.Nws tsis yog tsuas yog pom kev txaus siab xwb, tab sis nws kuj ntxiv qhov tshwj xeeb tactile kev paub rau cov khoom siv laminated.

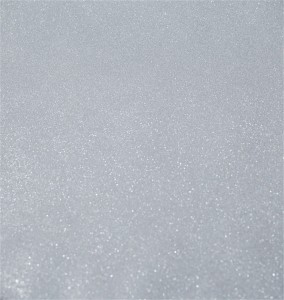

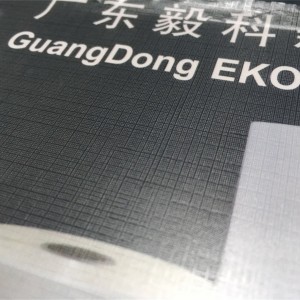

Muaj 4 hom embossing hauv EKO: kaum tus ntoo khaub lig, tawv, plaub hau, glitter.Txawm hais tias nws yog qhov zoo tshaj plaws ntawm kaum tus ntoo khaub lig embossing, nplua nuj ntawm tawv textures, ntxiv sparkle ntawm hairline embossing, los yog dazzling nyhuv ntawm glitter embossing, txhua txheej txheem coj ib tug kov ntawm khawv koob rau koj designs thiab transforms lawv mus rau hauv captivating daim duab.

Qhov zoo

1.Txhim kho qhov muag pom kev

Embossing ntxiv kev ntxhib los mos thiab qhov tob rau laminate, ua rau nws pom kev txaus siab thiab koom nrog.

2. Tactile kev

Los ntawm kev caw tib neeg los kov lub pob nyem, qhov kev paub tshwj xeeb yog tsim.

3.Branding thiab sib txawv

Cov txheej txheem embossing pab ua kom koj cov khoom sawv tawm ntawm kev sib tw.

4. Durability

Embossed thermal lamination zaj duab xis tsis tsuas yog txhim kho qhov pom thiab tactile nyhuv ntawm cov khoom, tab sis kuj ntxiv ib txheej ntxiv ntawm kev tiv thaiv.

5.Versatility

Embossing tuaj yeem siv rau ntau yam ntaub ntawv, suav nrog ntawv, cardstock, thiab ntaub.Qhov kev ua tau zoo no ua rau muaj ntau yam kev siv xws li daim npav lag luam, ntim khoom, phau ntawv npog thiab ntau dua.Embossing yog ib qho cuab yeej tseem ceeb hauv ntau qhov kev lag luam vim nws qhov yooj yim.

Peb cov kev pabcuam

1. Cov qauv dawb yog muab yog tias koj xav tau.

2. Teb ceev ceev.

3. ODM & OEM cov kev pabcuam kom ua tau raws li qhov xav tau sib txawv.

4. Nrog zoo heev ua ntej muag & kev pab cuam tom qab muag.

Kev pab cuam tom qab muag

1. Thov qhia rau peb paub yog tias muaj teeb meem tom qab tau txais, peb yuav xa lawv mus rau peb cov kws tshaj lij kev txhawb nqa thiab yuav sim pab koj daws.

2. Yog tias cov teeb meem tseem tsis tau daws, koj tuaj yeem xa peb cov qauv (cov yeeb yaj kiab, koj cov khoom uas muaj teeb meem nrog kev siv zaj duab xis).Peb tus kws tshuaj xyuas kev tshaj lij yuav kuaj xyuas thiab pom cov teeb meem.

Kev taw qhia cia

Thov khaws cov yeeb yaj kiab hauv tsev nrog qhov chaw txias thiab qhuav.Tsis txhob kub siab, noo noo, hluav taws kub thiab ncaj qha tshav ntuj.

Nws yog qhov zoo tshaj plaws siv hauv 1 xyoos.

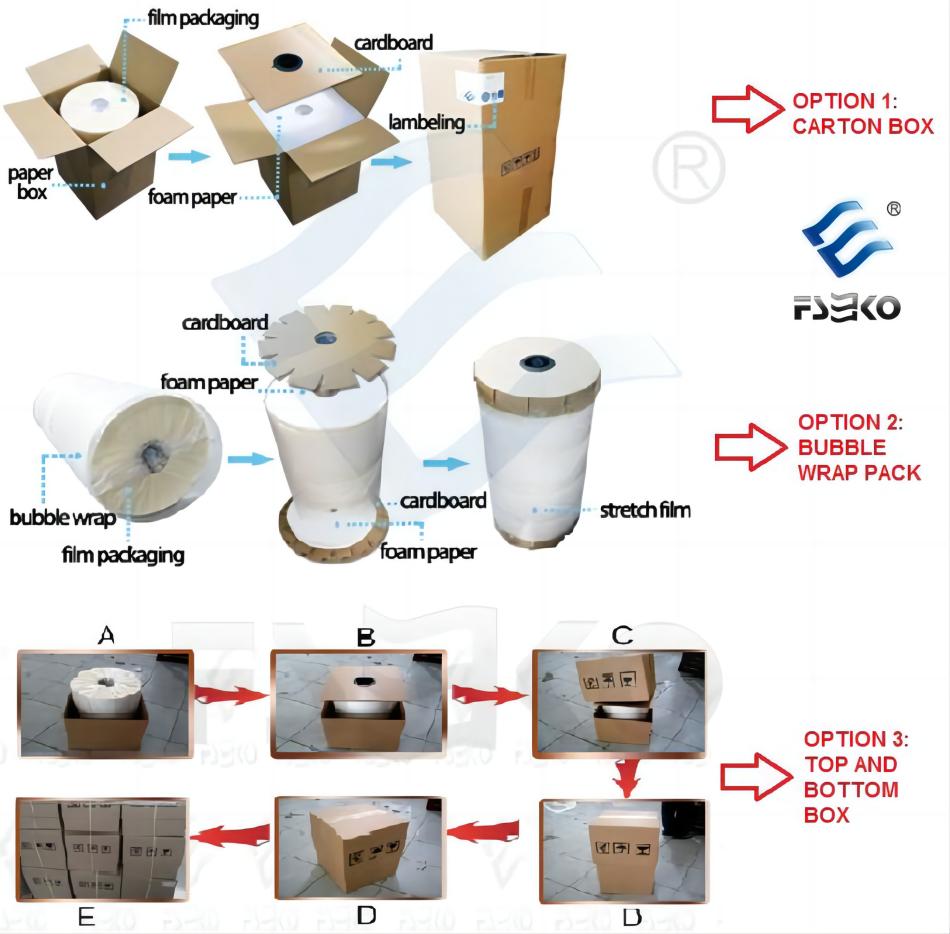

Ntim

Muaj 3 hom ntim rau koj xaiv