Hais txog thermal lamination zaj duab xis

Dab tsi yog thermal lamination zaj duab xis?

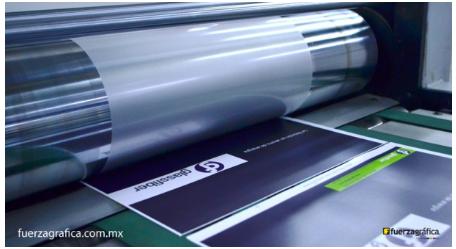

Thermal lamination zaj duab xis yog ua ntej txheej ntawm cov yas zaj duab xis nrog kua nplaum.Thiab cescua sov thiab laminatenrog ntawv luam ntawv.

Muab piv nrog cov txheej txheem txheej txheem, cov yeeb yaj kiab thermal lamination yog yooj yim rau kev khiav lag luam, tsis muaj kuab paug, thiab kev noj qab haus huv rau cov neeg ua haujlwm.Nws yog glossier thiab tuaj yeem khaws tau ntev dua, los tiv thaiv cov xim luam ntawv los ntawm kev hloov pauv.Nws yog tsis muaj wrinkles, npuas, los yog desquamates, uas yog haum rau ib tug zoo tib yam kub lamination tshuab.

Khoom siv rau laminating zaj duab xis:

Tshuab ziab thiab ntub dej laminating, nrog cua sov ua haujlwm

Kub: ib txwm luam tawm: 90 ~ 100℃;Cov ntawv tshwj xeeb: 100 ~ 110℃

Thermal zaj duab xis zoo

Nrog cov pob tshab siab, thiab nws tuaj yeem tau txais qhov zoo nkauj, nrog rau kev tiv thaiv cov luam tawm tom qab lamination.

Nws tsis muaj npuas, wrinkle lossis desquamate tom qab lamination;

Yooj yim rau kev khiav lag luam cov tshuab laminating, uas tuaj yeem txo tus nqi qis.

Cov khoom siv dav siv rau thaj chaw, haum rau kev tshaj tawm luam tawm, luam tawm digital.

Ua tau raws li kev cai ib puag ncig ntawm lub teb chaws occident, nws tau siv dav thoob plaws ntiaj teb

Tsis muaj kuab paug paug thaum lub sijhawm tsim khoom, nws yog ib puag ncig-phooj ywg thiab noj qab nyob zoo rau kev tsim khoom thiab kev siv.

Haum rau txhua yam kub laminating tshuab.

Ceev, kub thiab siab yog qhov tseem ceeb ntawm pre-txheej txheem txheej txheem

① Cov nplaum siv rau ua ntej-txheej yogEVA kua nplaumkub yaj nplaum.Yog li ntawd, nruj me ntsis tswj qhov kub thiab txias yog qhov tseem ceeb ntawmthermal lamination zaj duab xis.

② Vim tias qhov saum npoo ntawm daim ntawv tsis tiaj tus.Thiab cov viscous kub yaj nplaum yuav ua rau ntub dej ntawm daim ntawv luam tawm hauv cov txheej txheem ntawm kev tsav tsheb tawm ntawm huab cua ntawm cov ntawv luam tsuas yog nyob rau hauv qhov kev txiav txim siab..

③ Raws li qhov ceev ntawm lub tshuab laminating nce, qhov kub nias quab yuam txo qis, uas ua rau cov khoom sib xyaw ua haujlwm tsis zoo.Yog hais tias qhov kev khiav hauj lwm ceev ceev heev thiab kev sib txuas tsis ruaj khov, yuav muaj pos huab los yog blistering.

If you need some sample for your test , please contact us feel free admin@fseko.com.

Post lub sij hawm: Feb-15-2022