BOPP Thermal Lamination Gloss Film Rau Daim Ntawv Pov Thawj

Specification

| Khoom npe | BOPP thermal lamination glossy zaj duab xis | |||

| Thickness | 17 mic | 20 mic | 23 mic | 26 mic |

| 12 mic puag zaj duab xis + 5 mic ev | 12 mic puag zaj duab xis +8 mic ev | 15mic base zaj duab xis +8 mic ev | 15mic base zaj duab xis +11 mic eva | |

| Dav | 200mm ~ 2210mm | |||

| Ntev | 200m ~ 4000m | |||

| Txoj kab uas hla ntawm daim ntawv core | 1 nti (25.4mm) los yog 3 nti (76.2mm) | |||

| Pob tshab | Pob tshab | |||

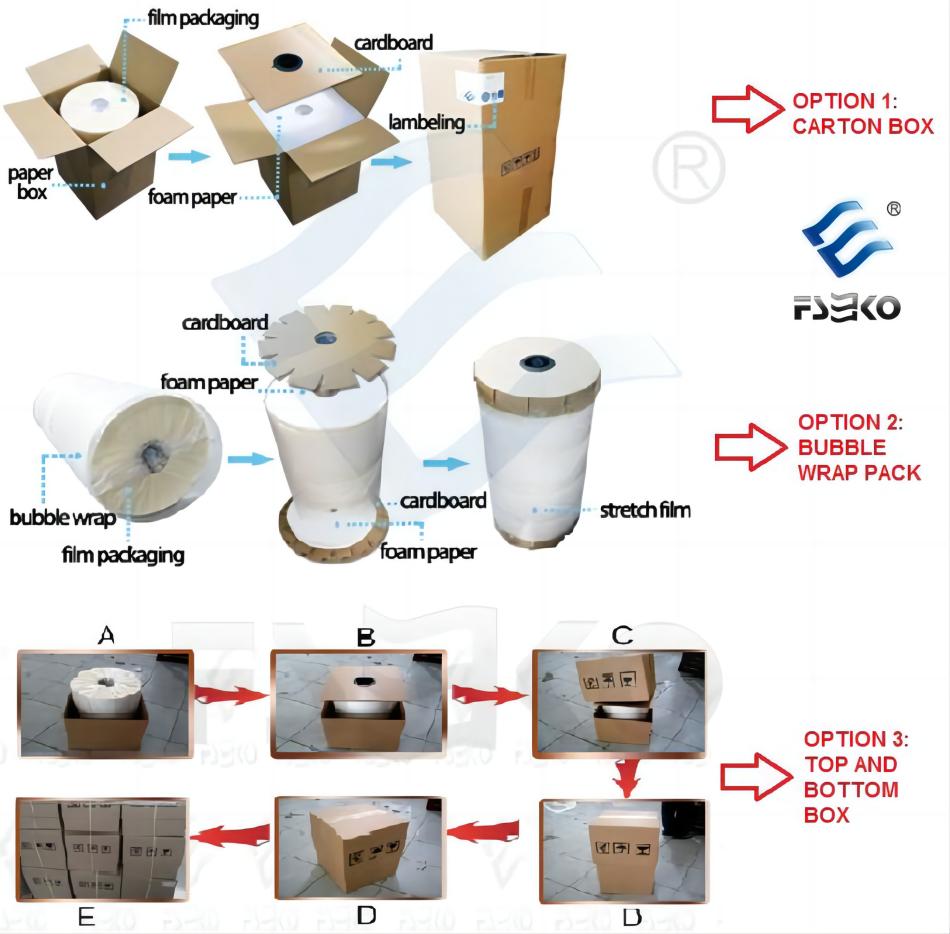

| Ntim | Npuas qhwv, sab saum toj thiab hauv qab lub thawv, thawv thawv | |||

| Daim ntawv thov | Cov ntawv xov xwm, phau ntawv, lub thawv cawv, lub thawv khau, hnab ntawv ... cov ntaub ntawv ntawv | |||

| Laminating temp. | 110 ℃ ~ 120 ℃ | |||

Product Description

Pre-txheej zaj duab xis yog tshwj xeeb tsim los ntawm yas zaj duab xis nrog lub tshav kub activated nplaum. Thaum tshav kub kub thiab siab yog siv los khi cov zaj duab xis rau saum npoo ntawm cov khoom uas tau laminated. Cov nplaum txheej melts thaum rhuab los ua ib qho muaj zog, pob tshab tiv thaiv txheej ntawm daim ntawv, duab lossis cov khoom siv. Nws tuaj yeem siv lub laminator uas muaj cov cua sov laminating muaj nuj nqi rau laminating.

EKO yog ib lub tuam txhab koom nrog R & D, ntau lawm thiab muag khoom ntawm thermal lamination zaj duab xis rau ntau tshaj 20 xyoo nyob rau hauv Foshan txij li thaum 1999, uas yog ib tug ntawm cov thermal lamination zaj duab xis kev lag luam txheej txheem setter. Peb muaj kev paub txog R & D cov neeg ua haujlwm thiab cov neeg ua haujlwm txawj, tsis tu ncua los txhim kho cov khoom lag luam, txhim kho cov khoom ua tau zoo, thiab tsim cov khoom tshiab. Nws ua rau EKO muab cov khoom tshiab thiab cov khoom zoo kom tau raws li cov neeg siv khoom sib txawv. Tsis tas li ntawd peb muaj patent rau invention thiab patent rau cov qauv siv hluav taws xob.

Qhov zoo

1. Eco-phooj ywg

Cov yeeb yaj kiab yog tsim los ntawm cov khoom siv rov ua dua tshiab, nws pab txhawb rau ib puag ncig ruaj khov thiab txo qis kev cuam tshuam ecological.

2. Customized loj

Los nrog ntau qhov sib txawv los ua kom haum rau koj cov khoom luam tawm.

3. Yooj yim rau kev khiav lag luam

Vim yog cov txheej txheem txheej txheej ua ntej, koj tsuas yog yuav tsum tau npaj lub tshuab ua kom sov (xws li EKO 350 / EKO 360) rau lamination.

Kev pab cuam tom qab muag

Thov qhia rau peb paub yog tias muaj teeb meem tom qab tau txais, peb yuav xa lawv mus rau peb cov kws tshaj lij kev txhawb nqa thiab yuav sim pab koj daws.

Yog tias cov teeb meem tseem tsis tau daws, koj tuaj yeem xa peb cov qauv (cov yeeb yaj kiab, koj cov khoom uas muaj teeb meem nrog kev siv zaj duab xis). Peb tus kws tshuaj xyuas kev tshaj lij yuav kuaj xyuas thiab pom cov teeb meem.

Kev taw qhia cia

Thov khaws cov yeeb yaj kiab hauv tsev nrog qhov chaw txias thiab qhuav. Tsis txhob kub siab, noo noo, hluav taws kub thiab ncaj qha tshav ntuj.

Nws yog qhov zoo tshaj plaws siv hauv 1 xyoos.

Ntim

Muaj 3 hom ntim rau thermal lamination zaj duab xis: Lub thawv thawv, npuas qhwv pob, sab saum toj thiab hauv qab lub thawv.